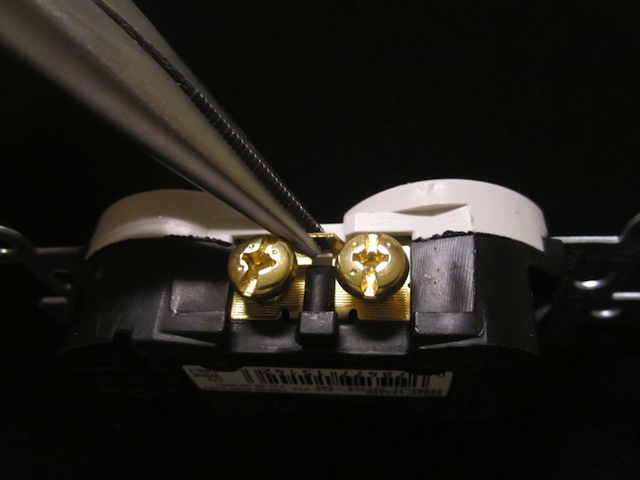

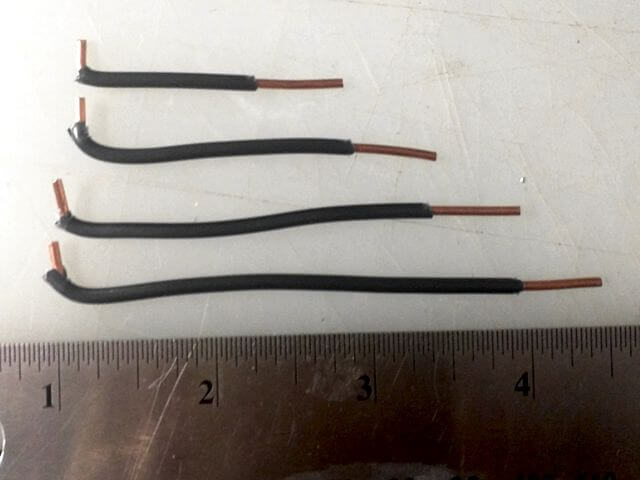

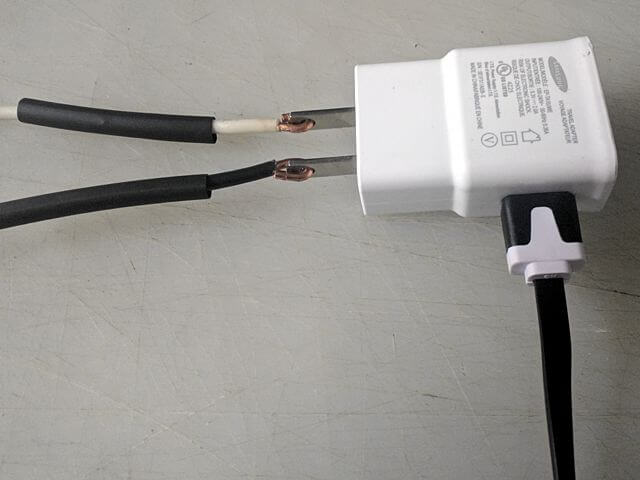

Pigtail solder the leads to the USB power adapter that you're gonna fit inside your box. This slightly big Samsung power unit just fits, and offers a lot of power out, but I've also used tinier format ones with success. Simply test that they give enough power by booting with them once (you did this earlier, right?). In this picture, I'm using 12-gauge solid wire, which is too heavy, and I ended up removing it and replacing it with lighter stranded gauge.

While I used my trusty soldering iron to make this connection, you could feasibly twist and wrap thinner wire and wrap in shrink wrap tubing for a suitable connection, considering how little jostling it might expect stuffed inside the box.

Note the shrink tubing just below the connection for sliding over the eventual soldiered connection. As this is polarized, either connection can go to either the hot or neutral lines, so I planned for how the USB was going to exit the adapter.

Final Hook Ups & Testing

Remember how I said to wait for doing the final hot hookups? We're at the final stretch.

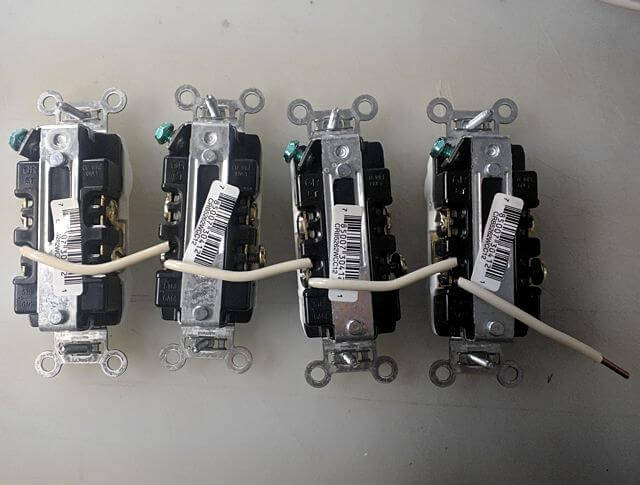

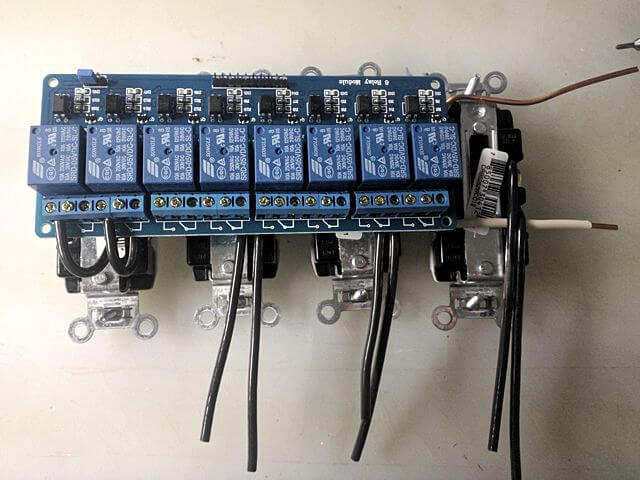

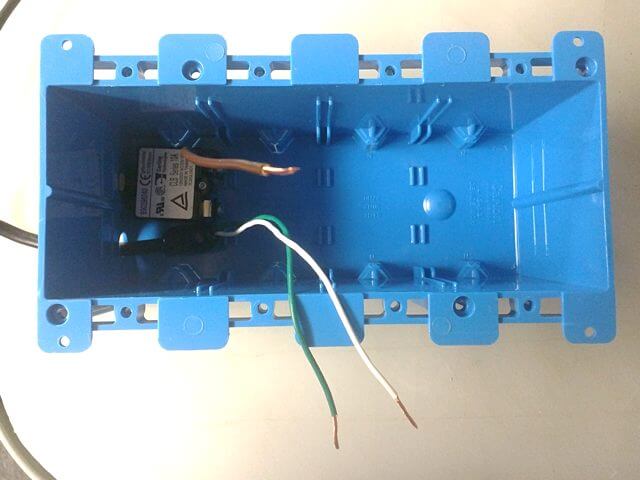

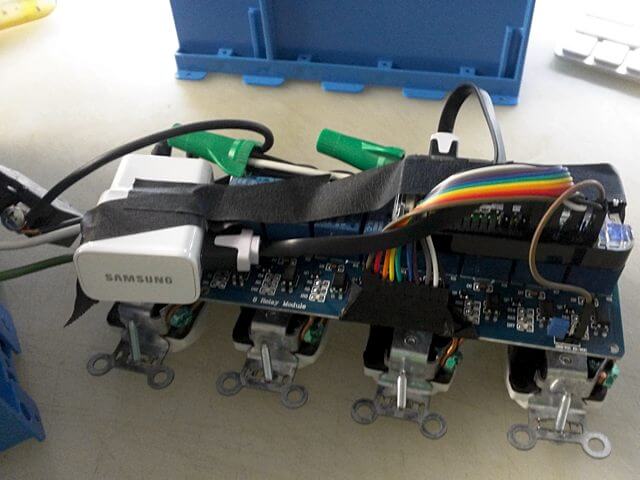

Figure where your USB power adapter is gonna fit in your final arrangement, and then take the two pigtail leads you just created and trim and strip one to be bundled into the final group of hot wires. This should have the right four common hot leads (already attached to the relay), as well as the jumper lead from the other bundle, and you should also include the USB power lead as well as the incoming hot lead from the work box. It's a lot of wires (6), and I found they just fit in my electrician wire nuts, especially since some of the leads were stranded and not solid wire. That completes the basic hot wiring.

Attach the other USB power lead to the same common neutral line by attaching it to an empty white neutral screw terminal on any outlet.

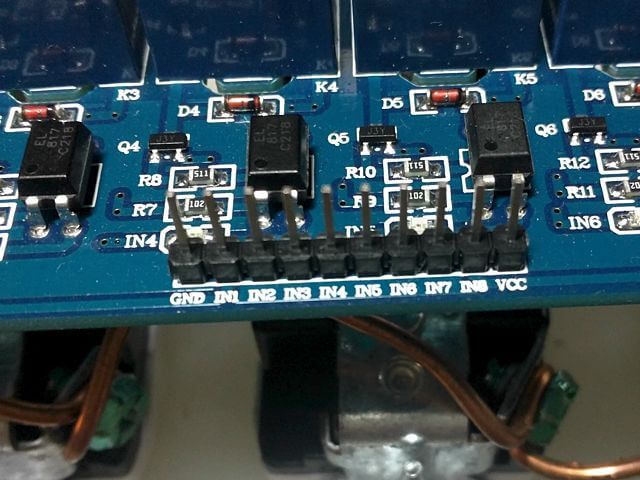

If you haven't already, hook up the USB power cable between the USB power supply and the Raspberry Pi, check the jumpers are all secure and seated on the Raspberry Pi and Relay board, and that all the wires are supposed to be where they are. If everything looks good and ready to go, you're ready for a live unboxed test.

You should run the Raspberry Pi headless, so unhook and HDMI and keyboards you might have attached. Plug in the box's power cord in the wall and look to the Raspberry Pi's LED to show you if it's booting. After some vigorous green blinking, you should once again see your device on your local subnet as http://shortname.local, and you can test each outlet and relay for functionality to your hearts content. When I tested, I noted I mis-wired and switched the 0 and 1 outlets to be opposite the others in the evens or odd. But every outlet worked without fail, no wires smoked, the breaker didn't blow and it hummed along nicely. Power down the Raspberry Pi again, (http://shortname.local/shutdown.php) and let's pack this into the work box.